- Overview

- Rotor

- Main purpose

- Packaging & Shipping

- Other products

Basic Info.

Model NO.

Rotor

Specification

customized

Trademark

DLK

Origin

Jining, China

HS Code

8439910000

Production Capacity

500 Square Meters Per Year

Product Description

Basic Info.

Main Specification

Product Description

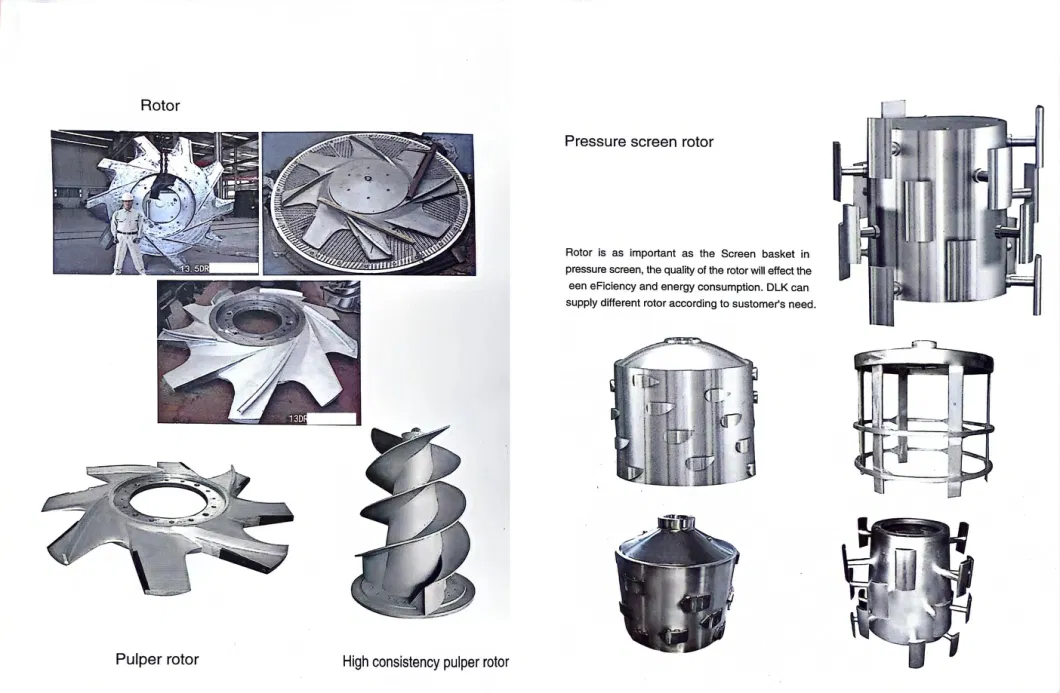

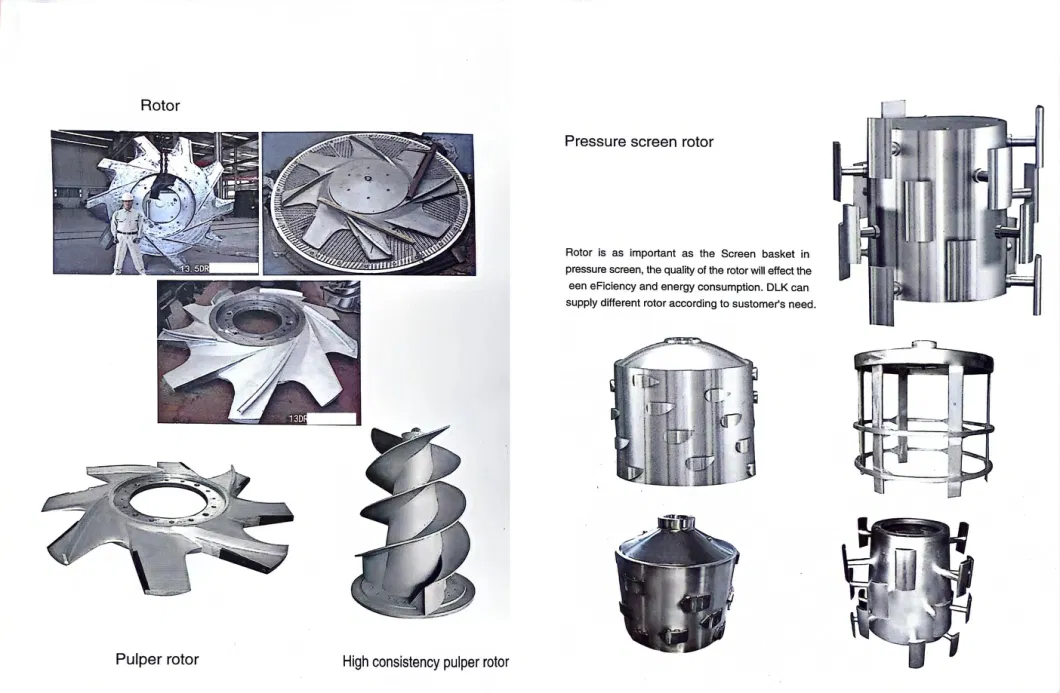

The rotor is an important component in a pressure screen, just like the screen drum.

The quality of the rotor determines the efficiency and energy consumption of the screening.

DLK provides different rotors according to the different process requirements of customers, bringing efficient and low consumption operating effects to your pressure regulation.

The pressure screen rotor rotates inside or outside the screen drum, and the rotor on the rotor runs closely against the screen drum. At the front of the rotor, the rotor exerts pressure on the slurry, causing it to pass quickly. At the rear of the rotor, negative pressure is formed, and the purified slurry repeatedly washes the screen drum to prevent clogging of the sieve holes.

The pressure screen adopts an upward flow structure design with bottom slurry feeding, bottom heavy slag discharge, and top light slag discharge, effectively solving the above problems. Light impurities and air in the slurry naturally rise to the top slag discharge port for discharge, while heavy impurities can settle to the bottom and be discharged as soon as they enter the machine body.

In this way, the pressure screen rotor effectively shortens the residence time of impurities in the screening area, reduces the possibility of impurity circulation, and improves screening efficiency. On the other hand, it prevents heavy impurities from damaging the rotor and screen drum, and prolongs the service life of the equipment.

Wooden crates or according to customer requirements.

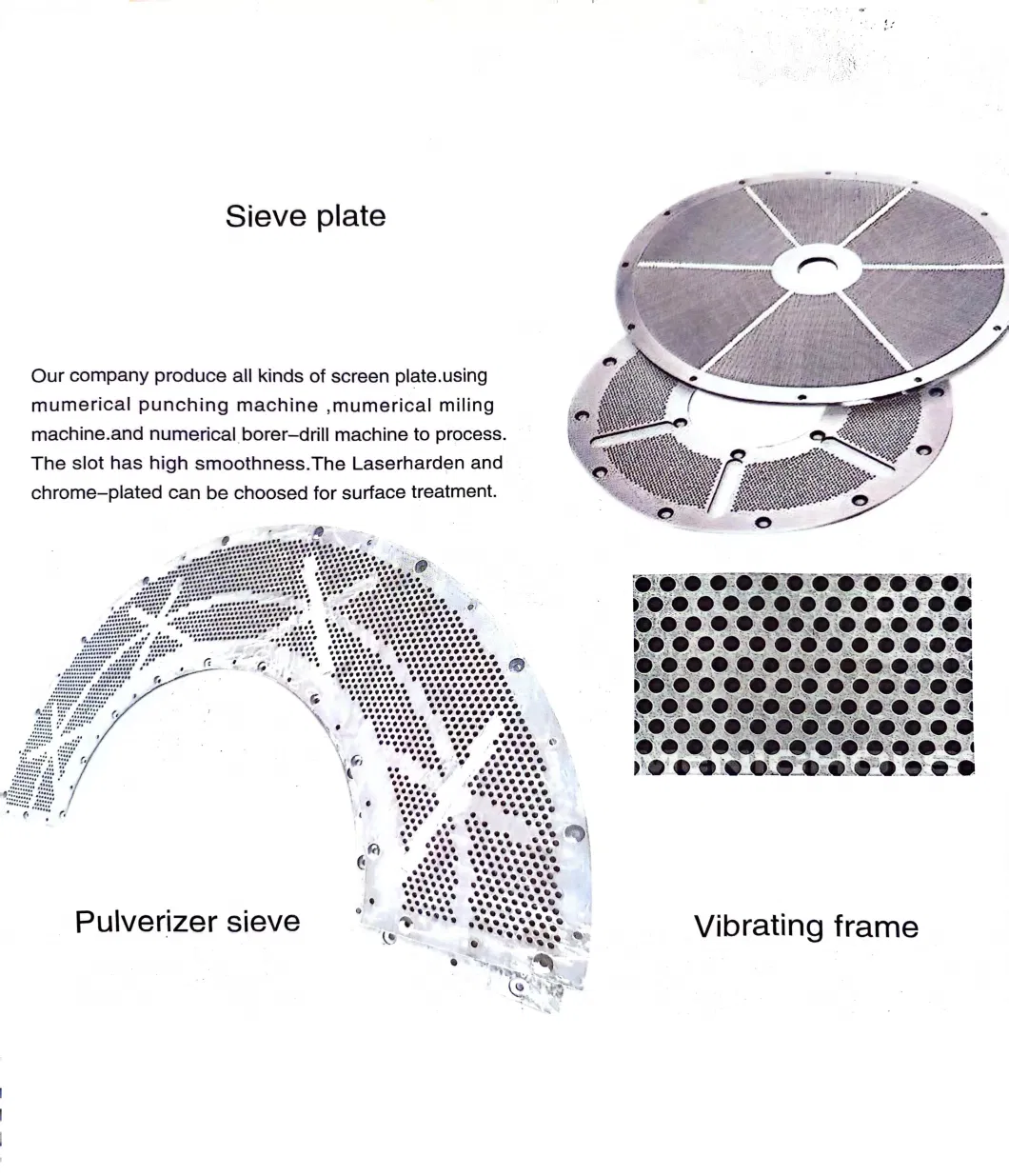

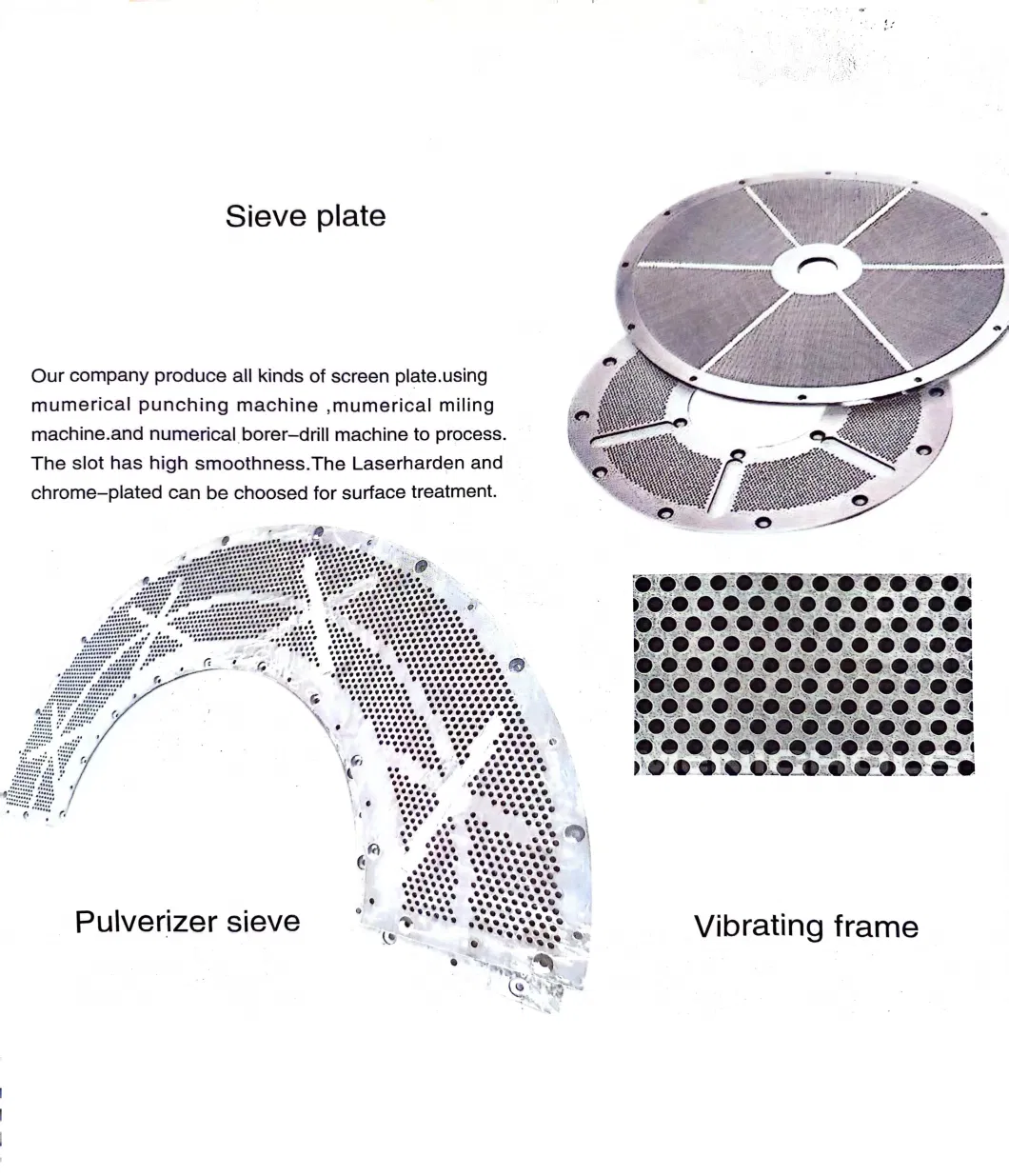

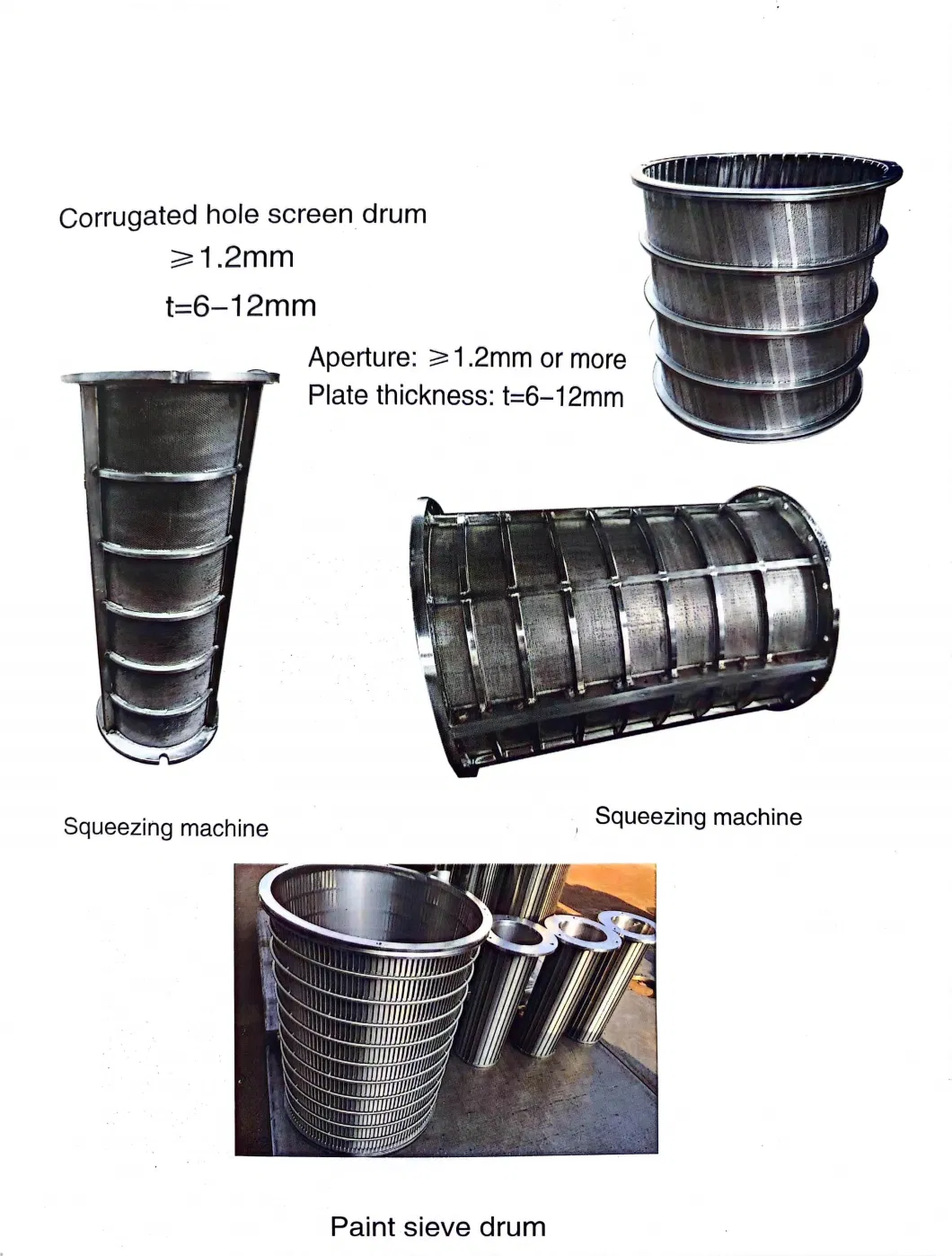

Sieve plate / Corrugated hole / Roughing machine / Oblique spiral thickener / Cylindrical sieve / Tailings sieve / Internal flow fine screening / Impurity separator

Abouat us

Delike Paper Machinery Co., Ltd. was established in 2015 and is a manufacturer specializing in the design, production, and sales of paper machinery and pulp equipment.

Our products sell well in Southeast Asia, the United States, Central Europe and other regions. The company mainly focuses on delivering high-quality products to the market and is committed to developing into an independent, scientific, and professional pulp and paper equipment manufacturing enterprise.

Adhering to the goal of providing high-quality, low consumption, and efficient products, we provide you with a complete set of professional pulp and paper making technical services with first-class service and reasonable prices.Striving for excellence and serving papermaking is our ultimate goal.

We look forward to your patronage and guidance to negotiate business!

| Condition | New | Material | Stainless Steel |

| Voltage | 380V | Function | Used for Pressure Screen Pulp |

| Transport Package | wooden case | Specification | Make to order |

| Trademark | DLK | Origin | China |

| HS Code | 843999000 | After-sales Service | Online Services |

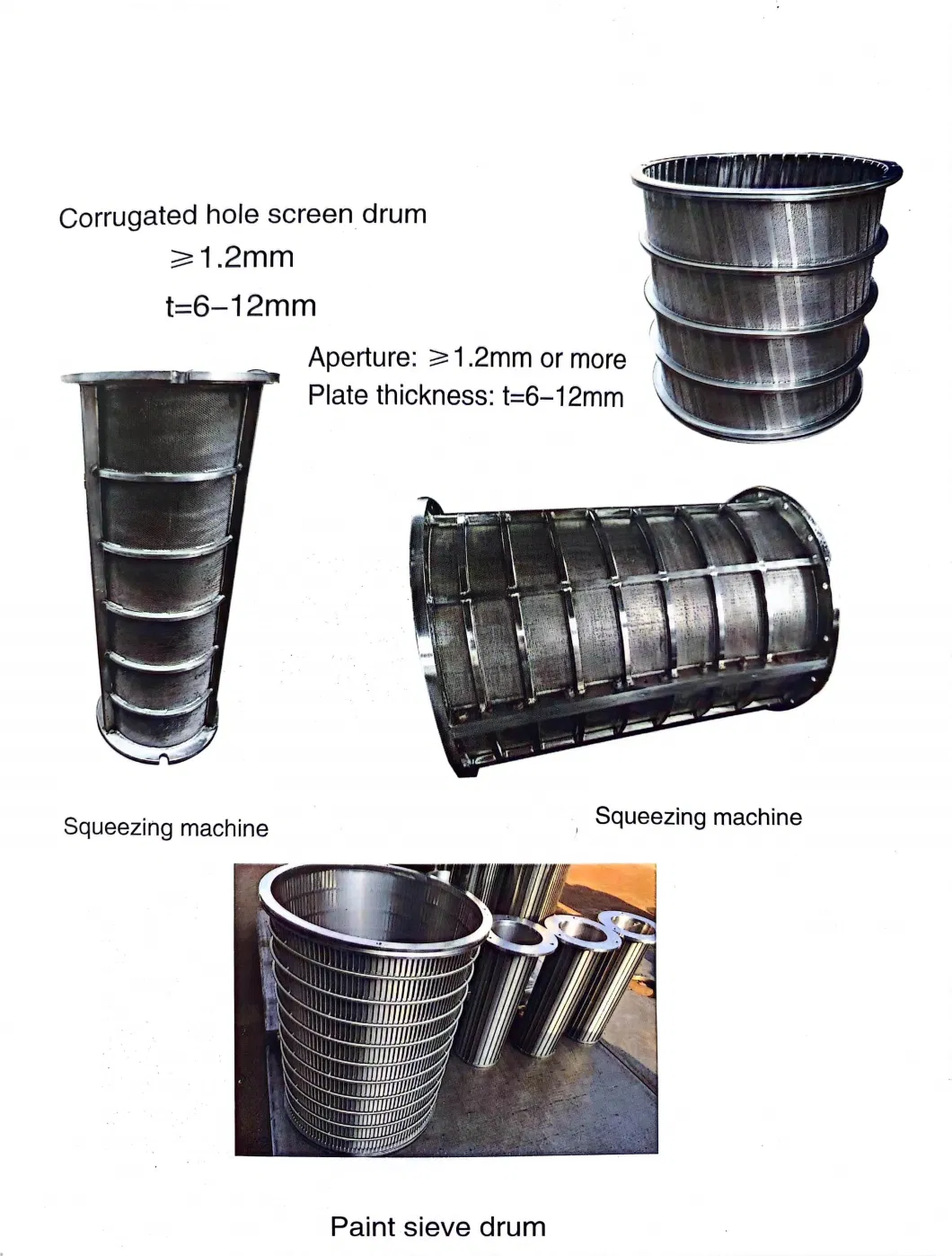

Main Specification

| Diameter range | 2000mm-1600mm | |||

| The smallest dia.of hole | 1.2mm | |||

| Material | SUS316L | SUS316 | SUS321 | SUS304 |

| Electro polished | Not centrifuging | |||

| Surface treatment | Laser harden and chorme-plated | |||

Product Description

The rotor is an important component in a pressure screen, just like the screen drum.

The quality of the rotor determines the efficiency and energy consumption of the screening.

DLK provides different rotors according to the different process requirements of customers, bringing efficient and low consumption operating effects to your pressure regulation.

The pressure screen rotor rotates inside or outside the screen drum, and the rotor on the rotor runs closely against the screen drum. At the front of the rotor, the rotor exerts pressure on the slurry, causing it to pass quickly. At the rear of the rotor, negative pressure is formed, and the purified slurry repeatedly washes the screen drum to prevent clogging of the sieve holes.

The pressure screen adopts an upward flow structure design with bottom slurry feeding, bottom heavy slag discharge, and top light slag discharge, effectively solving the above problems. Light impurities and air in the slurry naturally rise to the top slag discharge port for discharge, while heavy impurities can settle to the bottom and be discharged as soon as they enter the machine body.

In this way, the pressure screen rotor effectively shortens the residence time of impurities in the screening area, reduces the possibility of impurity circulation, and improves screening efficiency. On the other hand, it prevents heavy impurities from damaging the rotor and screen drum, and prolongs the service life of the equipment.

Wooden crates or according to customer requirements.

The following are the most popular products independently produced by our company, with high praise from customers for their quality and price.

Sieve plate / Corrugated hole / Roughing machine / Oblique spiral thickener / Cylindrical sieve / Tailings sieve / Internal flow fine screening / Impurity separator

Rotor / Pressure screen rotor /D-Type hydraulic pulp crusher / High(medium)concentration slag remover / Hydrapulper / Light slag separator/ External flow pressure screen

Abouat us

Delike Paper Machinery Co., Ltd. was established in 2015 and is a manufacturer specializing in the design, production, and sales of paper machinery and pulp equipment.

Our products sell well in Southeast Asia, the United States, Central Europe and other regions. The company mainly focuses on delivering high-quality products to the market and is committed to developing into an independent, scientific, and professional pulp and paper equipment manufacturing enterprise.

Adhering to the goal of providing high-quality, low consumption, and efficient products, we provide you with a complete set of professional pulp and paper making technical services with first-class service and reasonable prices.Striving for excellence and serving papermaking is our ultimate goal.

We look forward to your patronage and guidance to negotiate business!

FAQ

1.Q:Are you a manufacture?

A: Yes,we have been in providing the professional products in this field for 20 years.

2.Q:How to install the machine?

A:we can help with the installation by vedio,email,picture.if it is a large project,we can arrange our worker help you to install it in your country.

3.Q:How do you pack the products?

A:Normally as the export standard packaging or as your requirement.

4.Q:What's your available port of shipment?

A:Qingdao port,Shanghai port and so on.

5.Q:Is it customized available?

A:Yes,according to your detailed drawing you provided.